Disney’s cruise ships are an amazing feat of engineering. There are spaces onboard the ships for carrying food and preparing thousands of meals, a huge Broadway-level theater, pools, and hundreds of luxury hotel rooms. Somehow all of this moves through the seas at 25 miles per hour.

During the recent inaugural sailing of the Disney Destiny, I went below deck, backstage, to learn about the incredible inner workings of one of these massive ships. The sheer scale of the offerings was incredibly impressive. Mickey Visit brings you the latest Disney news and planning resources, including updates on Disney World construction and info on the lowest crowd dates at Disneyland.

READ MORE – These 10 Disney Rides Are Far Better Than The Ones They Replaced

Below Deck on Disney Destiny Cruise Ship

The Disney Destiny is the latest ship in the Disney cruise line fleet. We have our full review of the Disney Destiny here. The ship is one of three new vessels in the Disney Cruise Line fleet that first debuted with the Disney Wish. Not only are the designs of the ship visible to guests completely new, but the ships themselves have the latest technology to reduce ship emissions and conserve energy.

Disney Ride Closure ALERTS, Major Changes, Secrets Revealed

Get alerts on closures, park changes, exclusive discounts, and free printables. Trusted by 100,000+ Disney fans & planners.

The Chief Engineer of the Disney Destiny, Johan Blokstra, took a small group of media on a rare behind-the-scenes tour of the incredible technology that powers one of these three Wish class ships. We saw the massive Disney engines and the inner workings of other key systems that work together to reduce environmental impact from air conditioning, water, and fuel. This is a tour that every Disney Cruise Line fan dreams of.

We began our tour at the lowest deck accessible to guests. After passing through a door marked “crew members only”, we entered a maze of corridors and tight stairwells that are never seen by Disney Cruise Line guests. There are no windows in the areas we visited. The key sign that we were below sea level were the massive sliding doors that I assume are watertight separating different rooms down here.

Our first stop allowed no photos because of the sensitive nature of the systems we were watching. This is the engine control room. This room is so critical to the management of the ship that someone has been staffed here since the day that Disney took possession of the ship and someone will be staffed here for 24 hours a day for as long as Disney is operating the ship.

The room consists of a wall of screens and a long console with room for multiple people to sit here. On the screens are different sensors and indicators about how power is being used onboard the ship. It indicates where power is coming from and where it is going. These are the indicators that track every critical indicator for the health and efficiency of the ship.

During our tour, which took place we were in port, a large amount of the energy being used was for the chillers to power ship air conditioning. Other power uses include propulsion and general ship electricity.

There are also cameras looking at the engine rooms and critical areas below deck. This room is set up to monitor all critical ship functions. There is also a phone here to communicate with the bridge. The chief engineer shared that the captain on the bridge is largely in charge of steering the ship and relies on the engine room to have the power necessary for maneuvering. They also are in communication for things like fireworks nights when the ship may need to make more unusual maneuvers to ensure a good guest experience.

Previously, we have written about the incredible lengths that Disney Cruise Line goes to deliver an incredible experience for guests including their process to ensure the most beautiful days at sea possible and setting off fireworks at sea. See that story for more specific details.

There was also a map of the ship that was showing a red fire alarm when we were there. We learned it was nothing to be alarmed by. If something as small as a dishwasher opening and steam coming out sets off an alarm, someone will physically go check and confirm everything looks good.

This is also the helm of the process to reuse and repurpose energy onboard the ship. Throughout our tour, we heard over and over again about how some ingenious idea helped to reduce energy and water usage. For instance, heat from the engines is monitored and reused for power generation and air conditioning.

We learned that energy-efficient HVAC systems save nearly 700 tons of fuel per ship annually. They also repurpose condensation from air conditioning units for onboard laundry and save each ship approximately 10 million gallons of water annually.

The engineer shared how far this set up has come since the launch of the first Disney ship, the Disney Magic. Those ships have older technology and were built to follow different class regulations. Regulations from the International Maritime Organization, a part of the United Nations, around greenhouse gases and exhaust have changed over time. These govern shipping, cruise lines, and anything on the water. Disney has retrofitted their old ships with new technology, but this engine room set up is state of the art and brought all of the rules into the systems from the start.

READ MORE – We Go to Disney Every Week. Avoid These Rookie Mistakes.

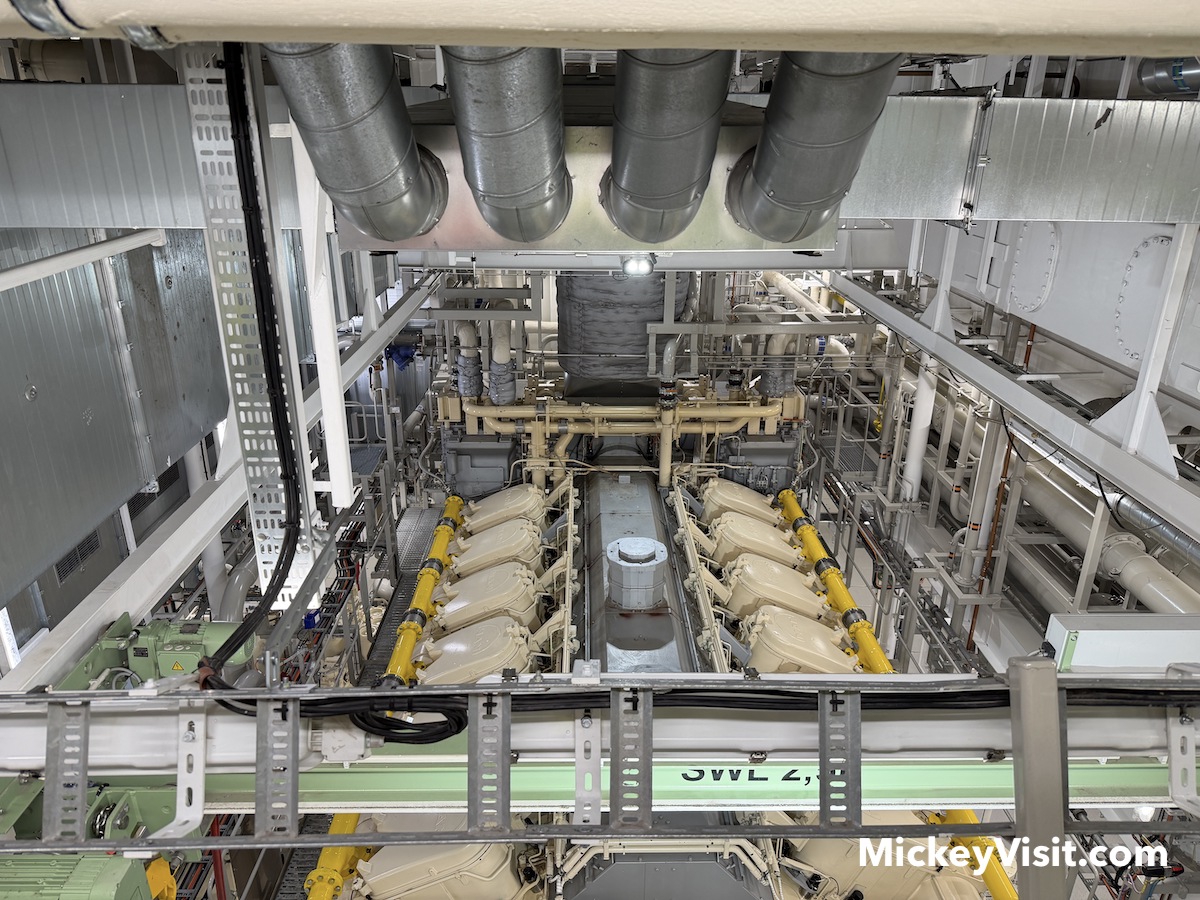

From here we put in our ear plugs and descended into the engine rooms. After heading backwards down steep stairs, basically ladders, we are in a bright white space with pipes running in every direction. The entire space was surprisingly clean and calm.

There are five engines down here that propel the ships and power the rest of the vessel. The ship’s engines run on liquefied natural gas. The fuel eliminates nearly all harmful sulfur oxide and particulate matter emissions while reducing both nitrogen oxide and onboard carbon dioxide emissions compared to traditional marine gas oil. The ship also has a hydrodynamic hull and specially designed propellers to save fuel by reducing the engine power needed to sail through the water.

The changes that Disney made to the engines for the Wish class ships resulted in a 20 percent reduction in greenhouse gas emissions compared to their older ships.

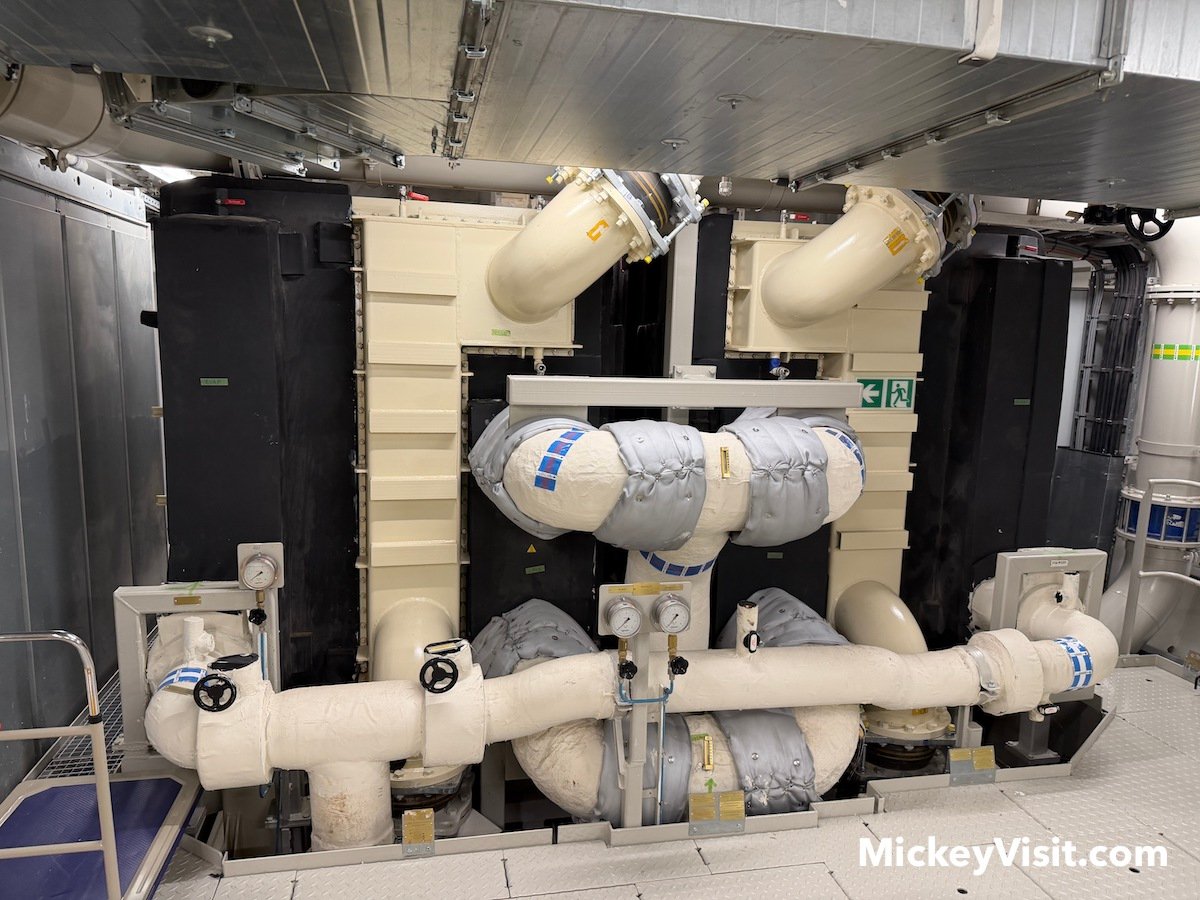

The engines also run the energy-efficient reverse osmosis systems that transform seawater for use across the ship. We saw the system where the Wish class ships produces up to 99 percent of its own freshwater onboard. The systems then also takes waste water and treat it to a point where it can be safely released into the ocean. Disney purifies water to a level far more pure than international regulations require.

The commercial laundry systems used for cleaning hotel bedding and towels, restaurant linens, and cast member costumes are intertwined with this reuse. In addition to using the water from the AC units, water from the last cycle of a load of laundry is then reused for the first load of the next cycle. It effectively reduces the amount of water needed for each load.

We also stopped to see a recycling station where Disney cast members hand sort dry garbage to pull out anything recyclable from the waste. Each ship in the Wish class recycles up to 400 tons of materials annually. They also shared that all used cooking oil is repurposed into a variety of fuels and products in port communities around the world.

At the end of our tour, we also learned about how Disney is working to reduce all single use plastic onboard the ships. We learned more from the Environmental Officer and saw a complete display of all the new replacements for single-use plastic. Each ship has an Environmental Officer who is responsible for the programs happening onboard.

Disney shared this full list of changes they have made to plastics:

- Replaced plastic straws with biodegradable ones

- Refillable bath product dispensers replaced single-use plastic bottles

- Reusable shopping bags in all merchandise locations

- Reusable cutlery and dishware at dining locations onboard and at island destinations

- 100 percent renewable wristbands replaced single-use stickers for Port Adventures

- Single-serve items like milk, cereal and yogurts served in reusable cups and bowls

- Castaway Club in-room amenities wrapped in paper or cardboard to replace plastic sleeves and bags

- Beverage station and specialty coffees served in new all-paper cups with all-paper lids

All of these efforts from Disney represent work to ensure that the sailings go off smoothly and in the least impactful way to the environment possible. Seeing what happens below deck gave me a greater appreciation of the seamless cruise experience. The next time that I am enjoying a soft serve on the pool deck, I’ll remember the incredible efforts going on more than 12 decks below me to make my experience safe, on schedule, and efficient.

Don’t Miss the Latest Disney News

Don’t miss the latest Disneyland and Disney World news from Mickey Visit. Join the FREE Mickey Visit newsletter that over 100k readers receive every single week. Mickey Visit is here to help you save money and experience more during your Disney and Universal vacation. See the Mickey Visit guide to Disneyland and the Mickey Visit guide to Disney World for tips.